12 Supply Chain Technology Trends To Watch In 2023

Millions of businesses across thousands of industries remain wholly dependent on the health of their supply chains. This became all too evident during the pandemic, when many of these chains suffered serious breakdowns, affecting the prices of products from microchips to medical equipment. In fact, the global supply chain is still reeling from many of the decisions made during 2020 and 2021.

But despite the complications that stem from supply chain globalization, it’s worth noting that the world’s supply chains are actually more efficient and reliable than ever. And, as with most other sectors of the economy, technological advancement is the primary driver of this increased efficiency.

Indeed, 2023 has already brought us a plethora of new supply chain innovations. However, at the rate technology moves, there are likely many more on the horizon. In this article, we’ll take a look at some of the biggest supply chain technology trends to watch for throughout the rest of 2023.

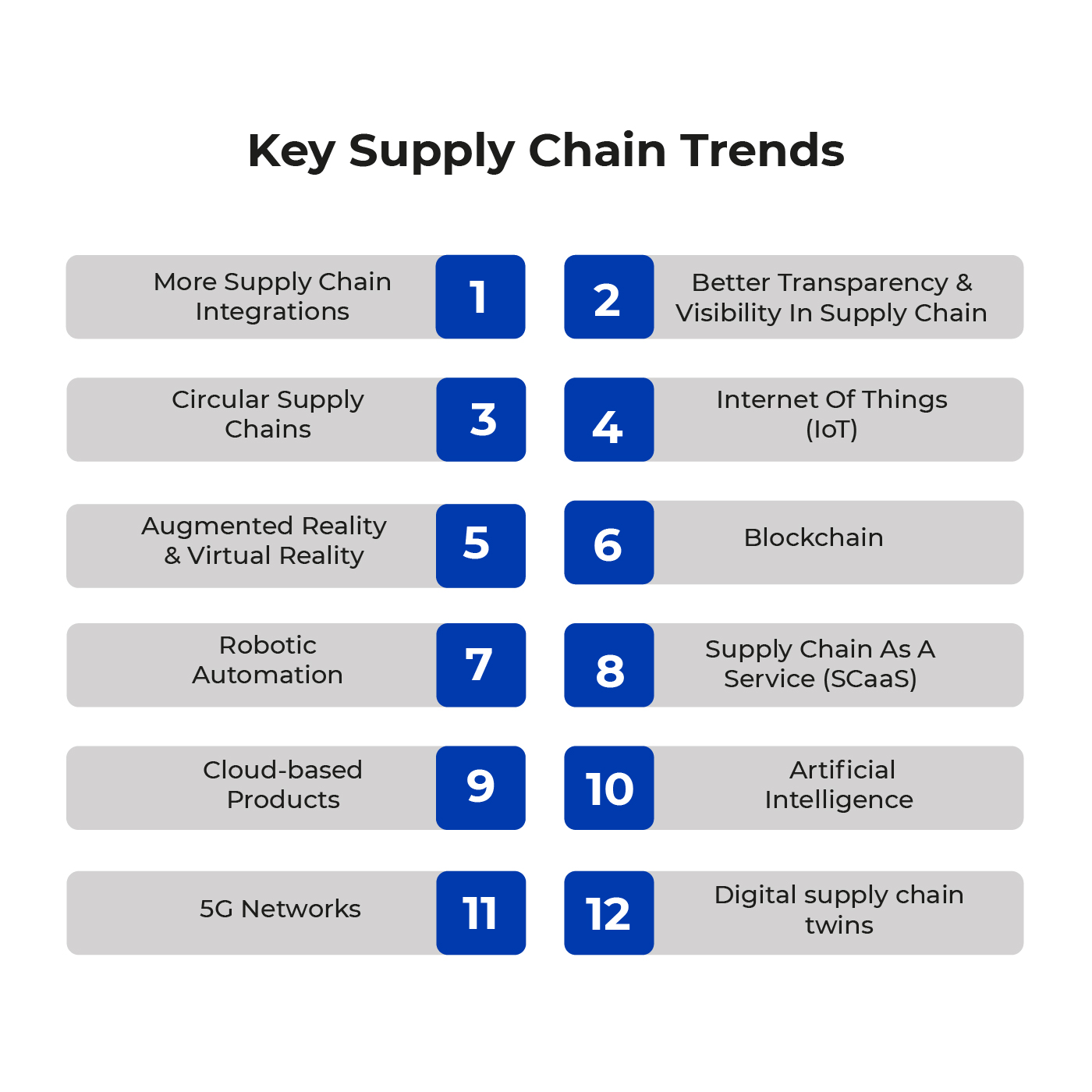

12 Supply Chain Technology Trends and Innovations

Before getting into our list of supply chain trends and innovations, let’s take a look at some of the supply chain-related problems these solutions are looking to solve.

For instance, right now, the technologies being prioritized in the supply chain industry mostly focus on data analysis, cloud computing, the Internet of Things, information security, and predictive analytics. That said, both third-party service providers and suppliers are not limiting their scope to just those six categories.

Indeed, supply chains are also attempting to embrace renewable energy at a pace not seen before. Moreover, more and more of their customers are demanding this sort of carbon consciousness. Of course, reconciling this with the increased need for technology-based solutions could create hurdles in the short term. Nonetheless, industries around the world are eagerly awaiting the arrival of new, improved tech.

Based on what we’ve seen so far and the research being performed by insiders, here are some of the supply chain management trends we can expect to see in both the short and long term.

More Supply Chain Integrations

2023 will see many new and innovative components added to supply chains, as companies around the world are eager to form partnerships and build integration with third-party service providers. In most situations, the goal will be to reduce freight costs, streamline delivery, or improve customer satisfaction. Integrations will vary in both cost and quality, but they are sure to be one of the most enduring supply chain trends going forward.

These integrations are particularly important to companies that operate on a global level, as “The Amazon Effect” continues to push them to reach new levels of efficiency. No doubt, we’ll see plenty of integrated management systems that utilize API or the cloud. If competition remains high, prices will decline to the point that nearly every supplier can find a suitable system.

Main Points

Larger suppliers continue to seek integrations to lower freight costs from any angle.

The Amazon Effect is pushing innovation in this sector.

Management systems that utilize the API and/or cloud technology are popular across sectors.

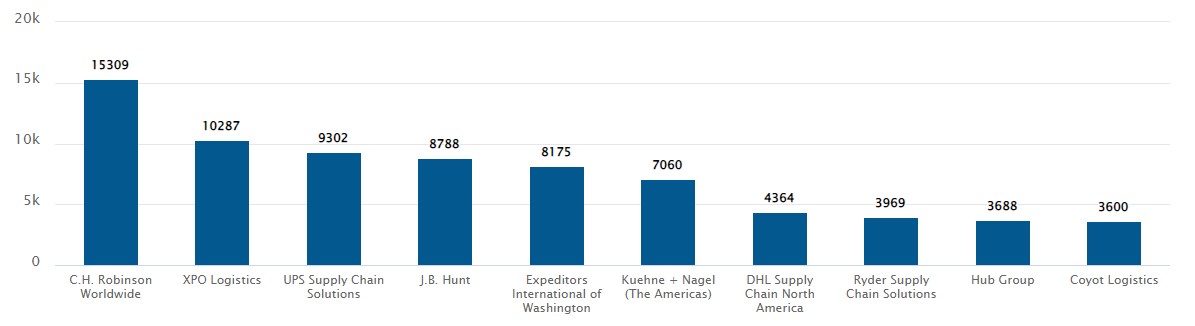

Top 10 Largest Third-Party Logistics Providers in the U.S. by Revenue (in millions)

Better Transparency and Visibility in the Supply Chain

Both the pandemic and ongoing climate concerns have raised questions about supplier authenticity. As a result, many buyers are looking for increased transparency levels, especially when it comes to sustainability, carbon footprint, and health standards.

Fortunately, companies are stepping up to the plate by providing detailed reports on their shipping practices, labor usage, and transportation investments. Many are even setting up digital dashboards and portals where their buyers can see the process inside and out.

Main Points

As global pushes for new regulations intensify, suppliers may be forced to adopt more transparent practices anyway.

Concerns over shipping practices and environmental impacts are the driving forces behind calls for increasing visibility.

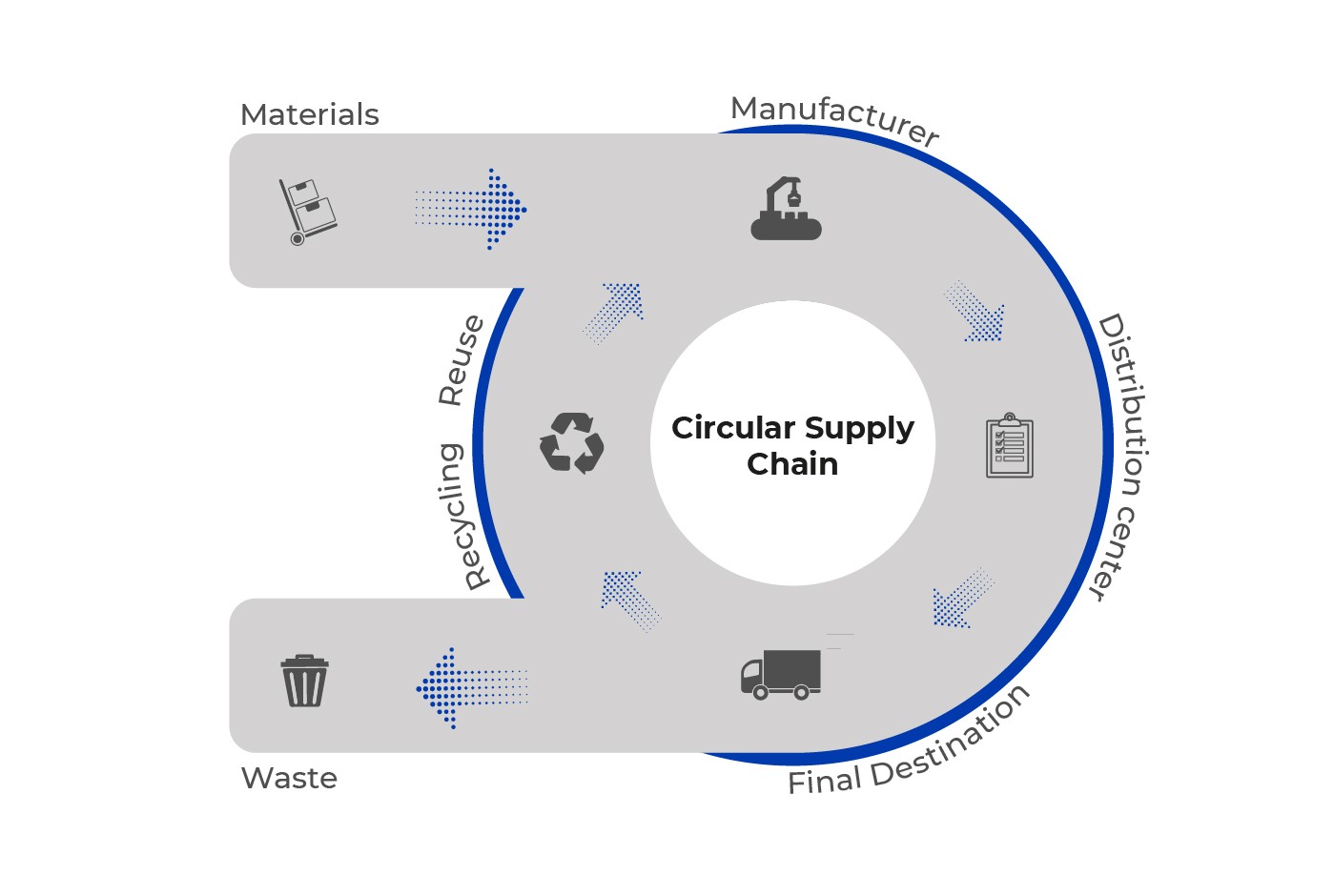

Circular Supply Chains

Nearly all insiders seem to agree that linear supply chains are on their way out, and circular supply chains are on their way in. The term circular supply chain refers to a situation in which manufacturers refurbish discarded products and then provide them for resale. The goal is to help stave off the ever-growing cost of raw materials and improve the company’s green reputation. By looping their supply chains, suppliers of all kinds can cut costs, reduce the impact of price volatility, and stay ahead of new government regulations.

Main Points

Many experts agree that circular supply chains will soon become the norm while linear supply chains will start to disappear.

Looping the supply chain helps companies reduce raw materials costs and better meet government regulations.

Of the various supply chain trends, this has one of the biggest potential impacts on the environment.

Internet of Things (IoT)

More and more companies have begun utilizing Internet of Things (IoT) devices to improve their supply chain visibility. For example, sensors on transportation can provide real-time tracking updates on shipping and delivery, while IoT technology in warehouses and retail outlets can improve production, inventory management, and maintenance.

This real-time information can help companies meet increasingly complex customer demands, minimize downtime, and boost overall efficiency. By contributing to the overall sense of visibility, IoT devices can help businesses optimize their assets and ROI via a constant flow of analytics and data.

Main Points

IoT devices are already helping companies boost their transparency and, therefore, their reputations.

These devices can also be integrated into ways that optimize suppliers’ ROI and provide valuable data on their operations.

Augmented Reality and Virtual Reality

As we’ll discuss in a few paragraphs, artificial intelligence is already being utilized to help automate procedures and predict purchasing demands. This is helping to make the plan of action far more efficient without any added manpower. Similarly, augmented reality and virtual reality can help suppliers improve worker productivity while supporting product development.

For instance, supply chain managers can use computer modeling to predict potential problems and plan an ideal response to disruptions. Such agility is crucial for suppliers who want to resist the impacts of natural disasters and global trade issues. Business owners can likewise optimize their supply chains by staying ahead of these trends and using technology to streamline procurement.

Main Points

AR and VR have huge potential to boost worker productivity while supporting new product development.

Alongside AI, these technologies are key to maximizing efficiency in a more complex world.

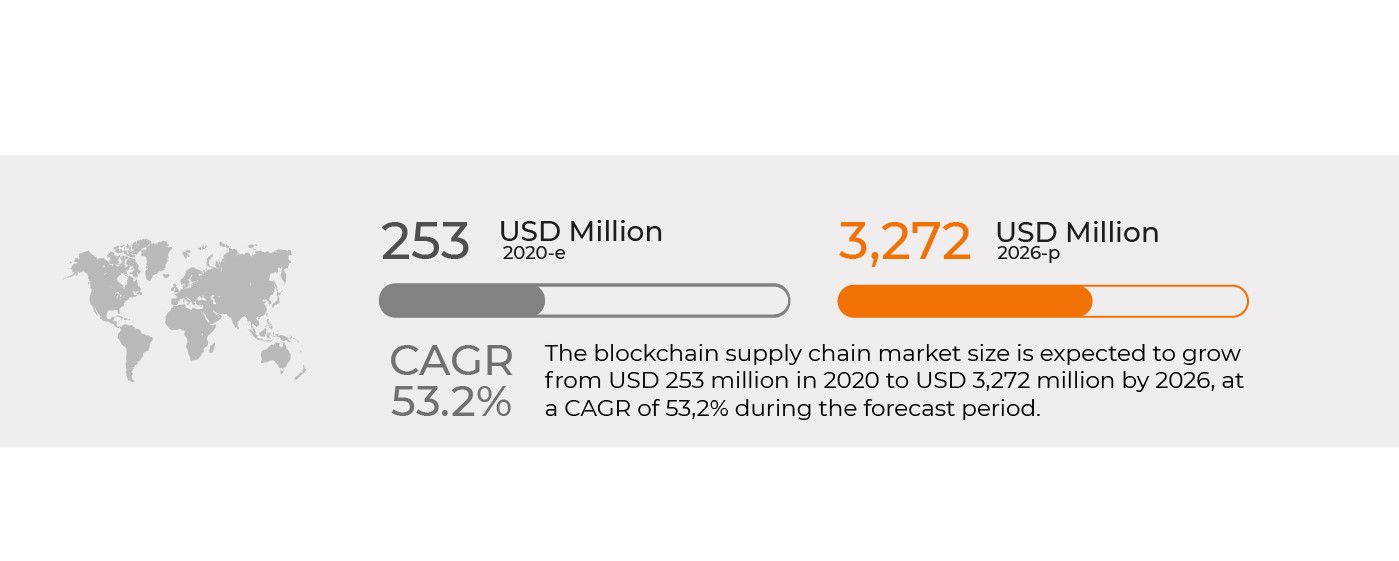

Blockchain

Many companies are worried about not being able to see their entire supply chain when needed. Fortunately, many have found that blockchain technology can help. Thanks to its unique structure, blockchain allows the whole supply chain to be seen on one platform, making it easier for everyone involved in the process.

For instance, carriers, shipping lines, forwarders, and logistics providers can use the same platform to keep everyone updated about the product journey. Meanwhile, payments can be made from the same system to streamline accounting and increase cash flow visibility. Using blockchain can not only help prevent problems before they happen, but it keeps data safe because no one can edit it without agreement from all parties.

Main Points

Blockchain has the ability to drastically improve supply chain visibility.

Blockchain provides incredible security since no one party can manipulate the data alone.

As blockchain moves past crypto, we can expect more and more suppliers to invest in the technology.

The global Blockchain Supply Chain Market size is projected to grow at a CAGR of 53.2% to reach USD 3,272 million by 2026. It was valued USD 253 million in 2020. Source - marketsandmarkets.com.

Robotic Automation

Robotics are transforming dozens of industries right now, and supply chains and logistics operations are no exception. Across the sector, companies are investing in drones and autonomous mobile robots to help them streamline operations and improve productivity. These technologies are designed to augment human efforts by automating procedures made up of simple, repetitive tasks while reducing human errors. This allows human workers to focus on more important jobs.

In many cases, warehouse workers can be redirected toward customer experience improvement. In the very near future, it’s possible we’ll see entire distribution hubs run by robots and AI.

Main Points

Robotics is being developed and utilized at a rapid pace all around the world.

Robots and drones can aid human workers by performing menial or repetitive tasks while they focus on more high-value jobs.

Many of these new devices can operate with minimal human intervention, allowing logistics managers to cut costs.

Supply Chain as a Service (SCaaS)

One thing most insiders agree on is that supply chains are becoming more complex and difficult to manage in-house. Due to a lack of skilled talent, many suppliers are switching to digital, utilizing IoT devices, and outsourcing critical business processes where possible. Supply Chain as a Service (SCaaS), as this concept has been dubbed, provides benefits such as better customer service, increased productivity, and reduced costs.

While the increased flexibility is a clear advantage, some suppliers are having problems relinquishing control. Hopefully, they will soon realize that the benefits greatly outweigh the downsides.

Main Points

More and more suppliers are outsourcing or automating processes due to a lack of skilled workers.

Much like SaaS, many insiders feel that SCaaS will soon evolve into a reliable industry unto itself.

Cloud-Based Products

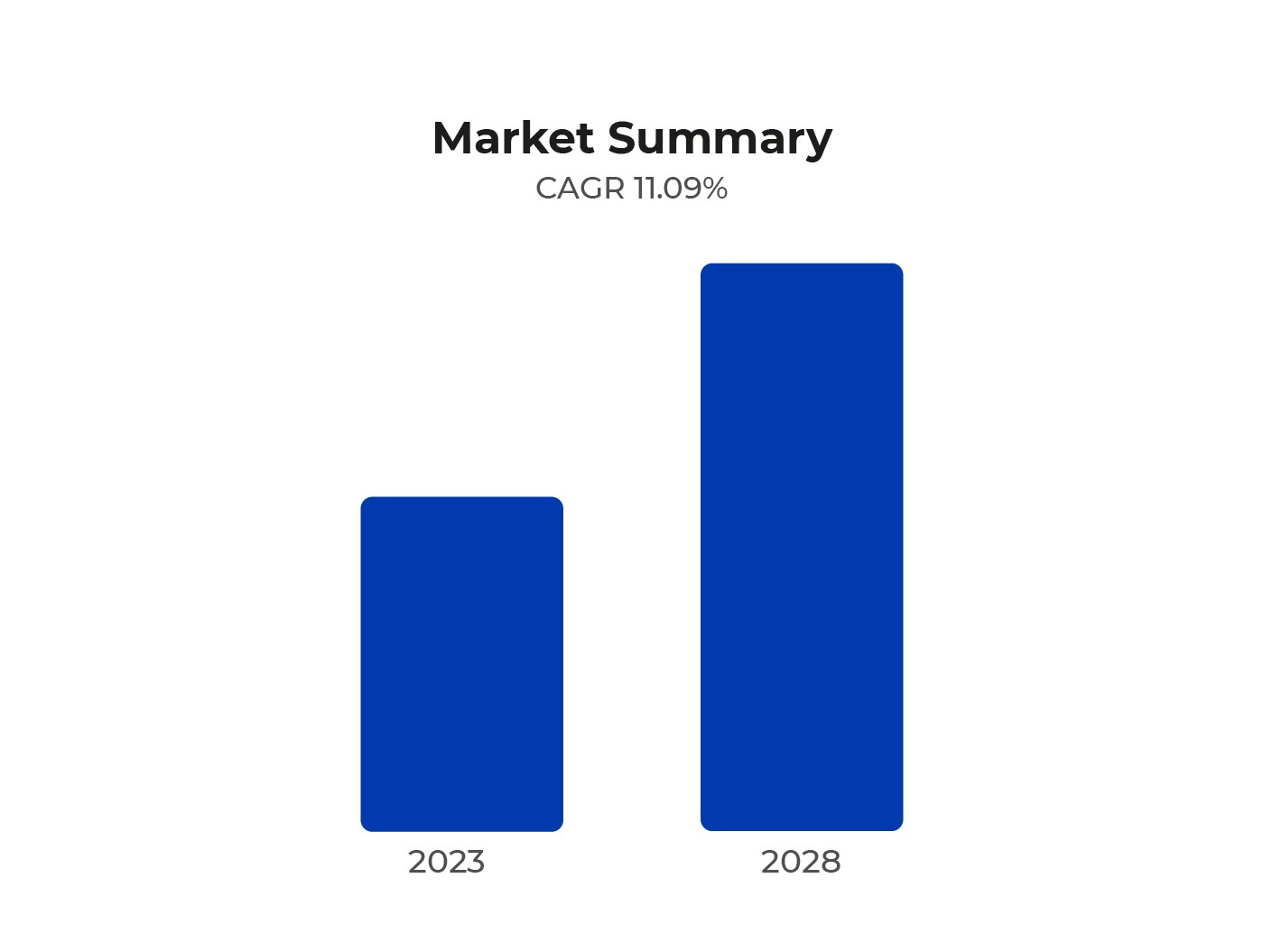

Cloud-based systems for supply chain management (SCM) offer similar functionality and security to on-premise solutions. However, they drastically reduce costs and customization issues. According to estimates, the cloud SCM software market is expected to grow to nearly $45.2 billion by 2028. Meanwhile, security concerns have diminished as vendors continue to invest in more reliable and trustworthy services.

Both cloud-based and on-premise solutions have benefits and can be customized to fit each supplier's ever-evolving needs.

Main Points

Working in the cloud is a great way to increase implementation speed and reduce costs.

The cloud-based software market is expected to grow exponentially as solutions improve.

The cloud supply chain management market is analyzed to grow at a CAGR of 11.09% during the forecast period (2022 - 2028). Source - mordorintelligence.com

Artificial Intelligence

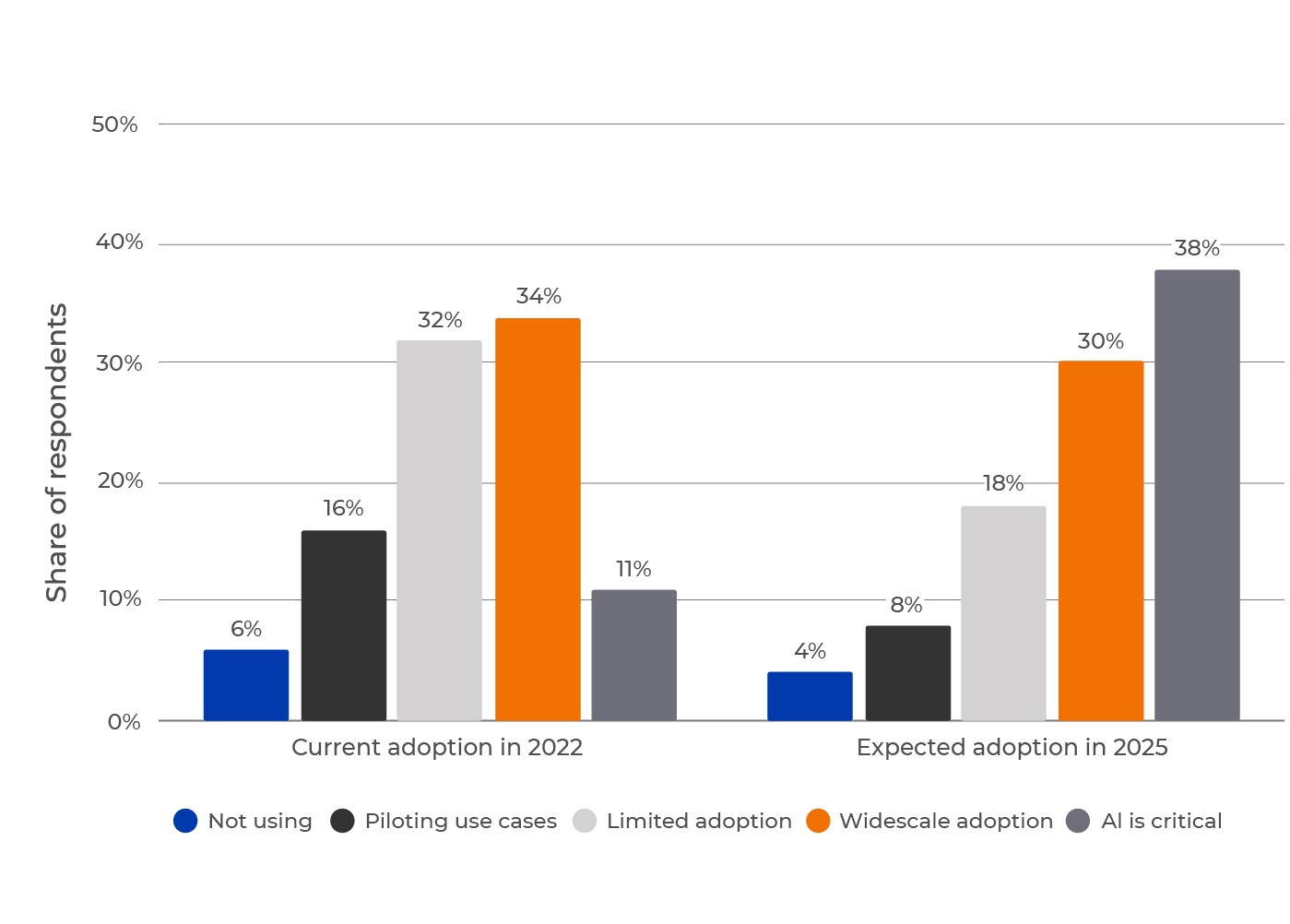

Automation has been trending across industries for the past decade. So, it’s no surprise that artificial intelligence (AI) is emerging as one of the biggest supply chain technology trends for 2023. Indeed, AI algorithms and machine learning enable businesses to proactively respond to demand changes, plan operations, identify cost-cutting opportunities, and automate warehousing procedures.

As more companies gain access to Big Data, AI and machine learning are becoming more feasible ways to streamline various aspects of their operations. It’s estimated that the predictive power of AI will even help suppliers detect trends in purchasing, potentially saving them millions down the line.

Main Points

AI is just one part of an overall supply chain automation trend that is increasing across the globe.

AI algorithms and machine learning could increase suppliers' ability to be proactive in the face of global challenges.

The potential for AI assistance in the supply chain and order management is virtually limitless.

Artificial intelligence (AI) adoption rate in supply chain and manufacturing businesses worldwide in 2022 and 2025. Source - Statista.

5G Networks

The emergence of 5G networks is expected to significantly impact the future of supply chain management. With the increasing prevalence of IoT-enabled devices, networks that can handle large amounts of data traffic are proving essential to supply chain refinement. Compared to 4G networks, which can support 10,000 devices per square mile, 5G can handle around a million devices.

As a result, this high-speed network will drastically improve the quality of communication between users, processes, and machinery. From logistics to distribution and warehouse management, the implications of this level of optimization are huge.

Main Points

5G can support roughly 100x more devices than the standard 4G network.

The high-speed network has the potential to facilitate rapid communication between users, IoT devices, and more.

Digital Supply Chain Twins

One thing the pandemic likely changed forever is how we work and communicate. Across industries, it is now completely normal for people to live and work hundreds or thousands of miles apart. As a result, making decisions regarding real-time data is now more challenging. Solutions include a concept known as “digital supply chain twins.” This essentially recreates an entire supply chain and all its various processes inside a fully-accessible digital environment.

If a supplier is already getting real-time data from integrated IoT devices, they can provide. In that case, they can provide their staff and clients with a highly accurate model of their business as various tasks are performed. That said, more than any other item on this list, creating digital supply chain twins requires a huge investment. No doubt, only the largest firms will be able to take advantage of the technology at first. Hopefully, competition will appear and start driving the costs down soon.

Main Points

Informed decision-making is to become extremely difficult due to physical distance.

Digital supply chain twins create a digital model of supply chain operations inside a virtual environment

When combined with other integrations, this can give unparalleled real-time insight into a supplier’s operation.

Though exciting, this technology remains cost prohibitive for now.

Conclusion

From supply chain management software trends to physical solutions like drones and robotics to solutions that improve risk management or provide data analytics, technology will be behind many of the changes we'll see. Though it’s possible that entirely new business models will be invented, the focus right now is to improve supply chain resilience while minimizing supply chain disruptions.

As business leaders and supply chain professionals become more open to these technologies, we’ll likely see entirely new supply chain strategies emerge, many of which will provide distinct competitive advantages – if only for a short time. Though Amazon remains the undisputed leader in e-commerce and logistics, supply chain software development services can significantly impact the playing field.

Related articles

The Discovery Phase of a Software Development Project: What It Is and Why You Need It

Dedicated Team Model - What It Is, Pros & Cons

AI in SaaS - Top Ideas and Trends in 2024 that will make a difference

- 12 Supply Chain Technology Trends and Innovations

- More Supply Chain Integrations

- Better Transparency and Visibility in the Supply Chain

- Circular Supply Chains

- Internet of Things (IoT)

- Augmented Reality and Virtual Reality

- Blockchain

- Robotic Automation

- Supply Chain as a Service (SCaaS)

- Cloud-Based Products

- Artificial Intelligence

- 5G Networks

- Digital Supply Chain Twins

- Conclusion