Must Have Inventory Management System Requirements And Features

Inventory management systems play an essential role in ensuring efficient and effective management of a company's inventory. These systems provide businesses with the tools and features to track, control, and optimize inventory levels. Though they vary in functionality, most allow users to account for all incoming and outgoing stock, which affects everything from accounting and production to sales and customer satisfaction.

In this article, we will explore some must-have inventory management software features and requirements. Whether you want to know how to build an inventory management system or want to upgrade an existing solution, this information can help your enterprise better meet customer demand while controlling inventory costs.

Remember, supply chain management software requirements constantly evolve. The best way to keep up is to remain informed and find a reliable partner.

What Is an Inventory Management System?

An inventory management system is a software solution that enables businesses to oversee and control their inventory from procurement to order fulfillment. It acts as a centralized hub, providing real-time visibility and accurate inventory data regarding stock levels, movement, and availability. With improved inventory tracking, companies can streamline business productivity, reduce costs, and better meet customer expectations.

Important Specifications of Inventory Management System

Certain specifications will always be crucial to optimal performance when creating an inventory system. Common Inventory control system requirements include:

Scalability – This allows the system to handle increasing inventory volumes as the business grows.

Automation – This helps reduce the manual processes associated with warehouse management, stock management, ad other business functions.

Security – Whenever you're utilizing a system that will hold inventory records, sales orders, and purchase orders, you want to ensure it has the latest security features.

Mobile Accessibility – The best Inventory Management Systems allow users to do their inventory planning on the go. It provides improved responsiveness, especially if a company has multiple locations.

Integration Capabilities – If your new IMS can seamlessly connect to other business systems (accounting, e-commerce, etc.), it will help streamline business processes down the line.

Easy Interface – Among the leading inventory management requirements is an easy-to-use interface. It helps reduce training time and the need for support.

As more companies invest in supply chain development services, requirements will only expand.

Top Inventory Management System Features by Category

Below, we’ve included some keys features for inventory management system design. Though warehouse functions differ from company to company, nearly every business will require particular features in the following categories.

Inventory Control – This feature handles products already in stock at the company’s warehouse. It typically involves tools for categorizing products, locating them by serial or SKU, and generating real-time reports and low-stock alerts.

Inventory Management - An inventory management system should support various basic warehouse functions, such as order processing, including order creation, tracking, and fulfillment.

Barcoding – Adding barcoding software can help reduce data entry issues by automating as much of the process as possible. It also makes collecting and organizing both items and data easier.

Forecasting and Demand Planning – One of the more advanced inventory management features is forecasting and demand planning. Essentially, these applications use algorithms to predict demand patterns and manage inventory levels accordingly.

Inventory Optimization – Inventory optimization is considered the next level of inventory management. It involves using tools that can automate steps in the process, produces reports based on past and current data, and generally improve supply chain management efforts across the board.

Inventory Management Features to Consider

Now that we’ve established some of the main categories of inventory management features, let’s take a look at some lesser-known or newer categories that may impact IMS capabilities.

Vendor Management - Effective vendor management allows businesses to maintain strong relationships with suppliers, manage purchase orders, track vendor performance and inventory.

Reporting and Analytics – Intuitive reporting and analytics capabilities provide businesses with valuable insights into their inventory performance. It can also aid in purchase order management, transfer management, and turnover reports.

Cloud Infrastructure - Cloud-based software is a scalable, cost-effective solution. Though it is not essential, it has become one of the most popular inventory tracking system requirements, especially when multiple locations are involved.

Internet of Things Integrations – The Internet of Things offers countless solutions for companies of all sizes and types, from RFID tracking and digital labeling to GPS tracking etc.

Mobile Systems – A mobile system might be the most logical choice, depending on one’s particular inventory management system implementation guidelines. Many of these IMS solutions run on tablets, iOS, or Android.

Machine Learning and AI - Though it is by no means one of the essential functionalities for inventory management systems, machine learning can analyze data to help improve supplier management, reduce shipping costs, and create a recommended safety stock.

Essential Requirements of an Inventory Management System

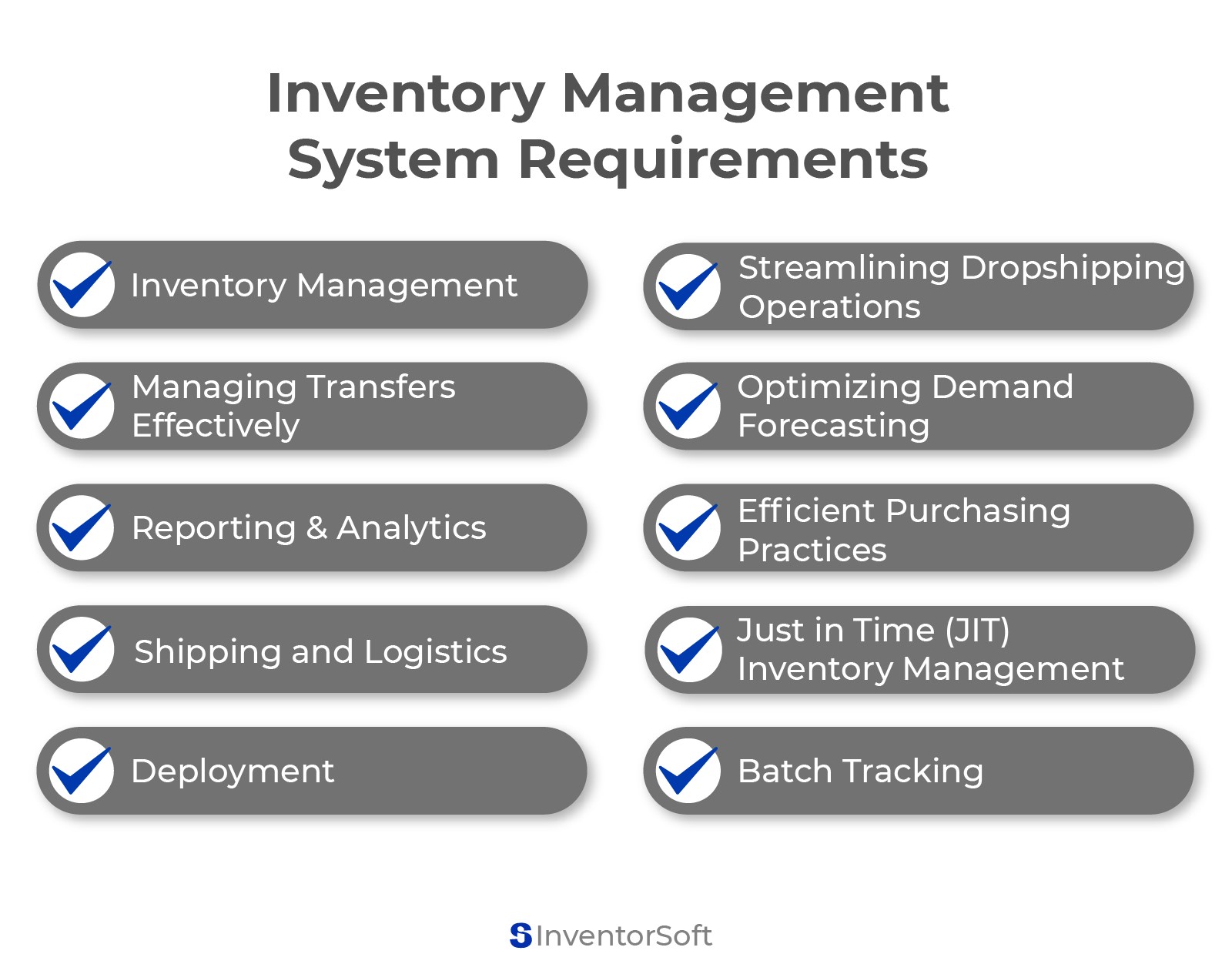

The team at InventorSoft has analyzed a wide range of inventory management system evaluation criteria. Looking at the various features, categories, and specifications above, we’ve come up with a list of essential IMS requirements. Consider this a list of best practices for inventory management software selection.

Inventory Management

An essential requirement of an inventory management system is to handle all aspects related to inventory control efficiently. This includes accurately tracking stock levels, monitoring item movements, and organizing inventory data. The system should enable businesses to easily view, manage, and update their inventory information to eliminate data silos, streamline operations, and make informed decisions regarding stock replenishment. Finally, users might consider a concept known as Vendor Managed Inventory, that is a unique solution suitable for longer-term business relationships.

Features include:

Product Categorization

Product History

Collaborative Inventory

Automated stock out Reports

Vendor Managed Inventory

E-commerce

Stock Inquiries

Managing Transfers Effectively

A reliable IMS should facilitate moving inventory between different locations or warehouses, tracking transfer orders, and updating stock levels accordingly. Such a feature is important because it allows companies that handle multiple sites to move their inventory where it will provide the most value. What matters is that the system provides clear visibility of transfer statuses, facilitates enhanced inventory control, and minimizes stockouts or overstocks.

Features include:

Order Picking

Voice Picking

Multi-Location Tracking

Stock Transfer

Pick-To-Light

Reporting & Analytics

Comprehensive reporting and analytics capabilities are among the best inventory optimization system requirements in any IMS. The goal here is to generate reports regarding things like stock levels, sales trends, order history, and inventory turnover. This helps businesses assess their inventory health while providing them with valuable insight into inventory performance. Ultimately, this data helps establish inventory metrics and KPIs, which can aid in making data-driven decisions that reduce safety stock and cut carrying costs. Ultimately, inventory forecasting software capabilities are a huge bonus for any business, regardless of industry.

Features include:

Report customization

Report integration

Easy-to-use dashboards

KPI and metric assistance

Shipping and Logistics

Another of the most in-demand inventory management system features is the ability to seamlessly integrate that solution with one’s shipping and logistics operations. This can make tasks like labeling and multi-carrier shipping much easier while also ensuring customers get their goods as quickly and efficiently as possible. Depending on the software of choice, the IMS may allow users to print shipping labels, track shipments, and manage order fulfillment processes from the same place. Finally, coordinating with shipping carriers' APIs can provide real-time tracking information and automate shipping updates.

Features include:

Shipment by ID

API integration

Labeling

Multi-carrier Shipping

Multiple Shipment Orders

Deployment

An IMS with flexible deployment options is ideal, as both on-premise and cloud-based options have their own benefits and drawbacks. Ultimately, it’s best to allow businesses to choose the option that best aligns with their infrastructure and scalability requirements. Of course, cloud-based inventory products offer easy access, scalability, and automatic software updates. However, on-premises deployment provides greater control and security for businesses with specific compliance needs. Whichever choice they make, the system should ensure a seamless and efficient deployment process to minimize disruptions and enable businesses to leverage inventory management as soon as possible.

Streamlining Dropshipping Operations

More and more companies are embracing the dropshipping business model to create passive income. If this sounds like you, it’s essential that your inventory management system effectively facilitate your dropshipping operations. Ideally, your IMS would be able to seamlessly integrate with dropshipping suppliers, automatically forward orders to suppliers for the fulfillment, and update tracking information to customers. As with any other operation, real-time visibility is a huge bonus here, as it can help companies better manage supplier relationships while expanding product offerings and reducing inventory holding costs.

Features include:

Automated ordering and fulfillment

Sourcing management

Supplier management

Real-time visibility

Optimizing Demand Forecasting

Comprehensive demand forecasting capabilities can help businesses accurately predict when their customers will be ready to buy. These applications can analyze historical data, market trends, and seasonality to generate demand forecasts for different products and SKUs. By optimizing demand forecasting, businesses can improve inventory planning, reduce stockouts and overstocks, and create reorder points that trigger automatically throughout the year.

Features include:

Stockout protection

Market trend analysis

Sales control

Automated reorders

Efficient Purchasing Practices

A good purchasing solution will enable businesses to automate purchase order generation, manage supplier relationships, and track order statuses. Many of the best examples will start with templates, then populate them with existing data pulled from other parts of the IMS. This can provide visibility into supplier lead times and pricing, thus facilitating informed purchasing decisions.

Features include:

Purchase order

Automated purchase order generation

Receiving

Supplier management

Order status tracking

Mobile Support

Mobile support allows businesses to access and manage their inventory data on the go. To enable this, many solutions offer mobile websites or dashboards that can be accessed by phone, tablet, or other mobile devices. From here, users can perform inventory-related tasks, such as viewing stock levels, creating orders, and tracking shipments, anywhere they can find an internet connection.

Features include:

Mobile website

OS for different devices

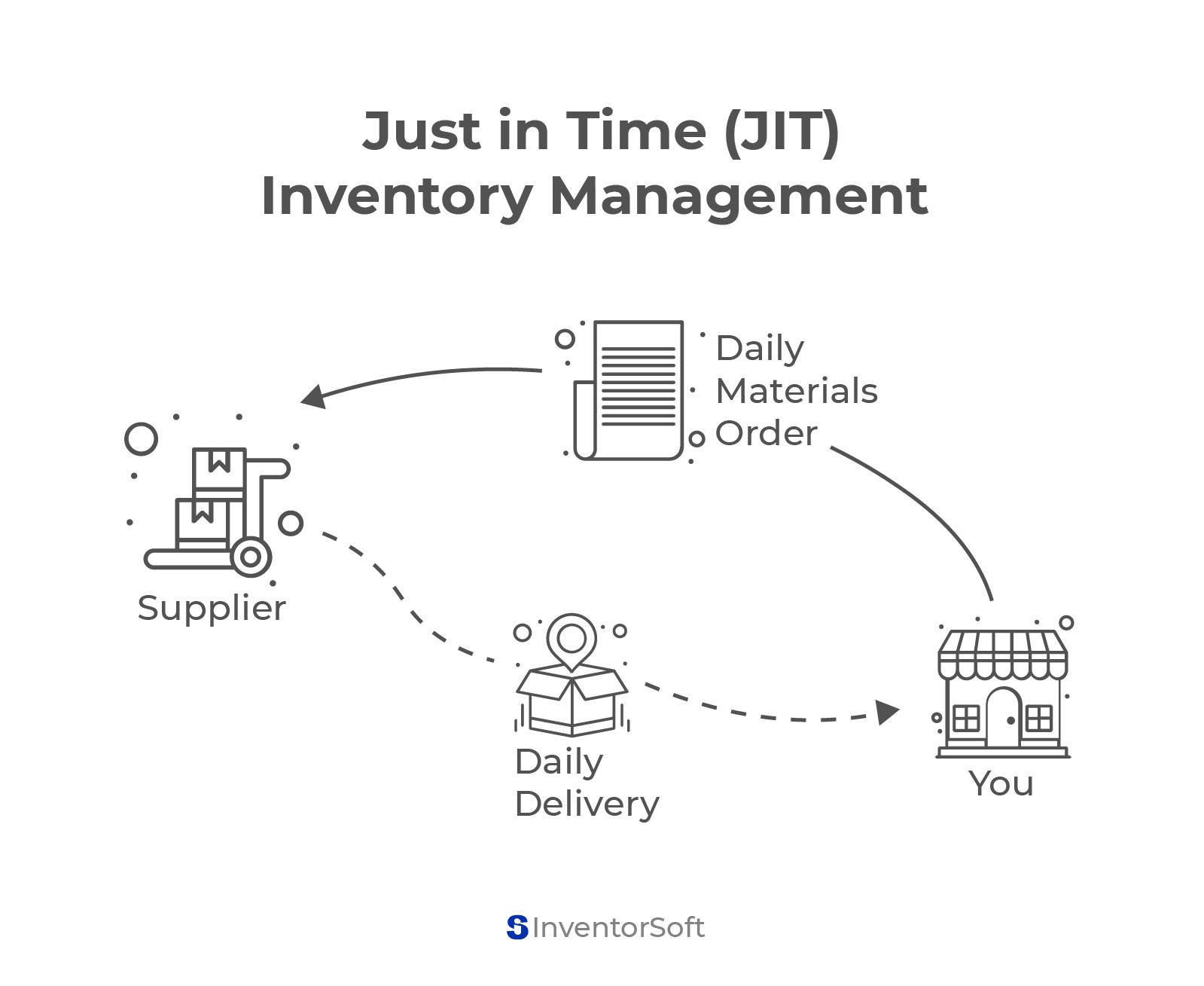

Just in Time (JIT) Inventory Management

Just in Time (JIT) inventory management refers to a situation in which a warehouse carries the minimum inventory quantity necessary to meet demand. Doing so lowers inventory costs while eliminating the risk of product loss and dead stocks. To pull this off, a system should provide accurate demand forecasting, support automated reordering or replenishment, and facilitate efficient supplier management.

Inventory alerts

Forecasting

Automated reordering and replenishment

Batch Tracking

The best IMS solutions allow users to track and manage inventory by batches. This is particularly crucial for businesses dealing with perishable goods, pharmaceuticals, or products with specific manufacturing or expiration dates. The system should enable businesses to assign batch numbers to products, track batch movements, and ensure proper rotation to minimize waste and comply with regulatory requirements. It can also be useful in the event of a producer recall.

Crucial Integration Requirements

A good IMS should work well on its own. However, as the supply chain becomes more digitized, it becomes more important that all the various applications, APIs, and software types be able to speak to one another. When considering investing in an inventory management system, make sure it can integrate with the following:

E-commerce Applications

Integration with e-commerce applications is a big benefit for an IMS. This allows users to automatically synchronize inventory data between the IMS and one or more e-commerce platforms while ensuring the information on the online store is accurate and up-to-date. Ultimately, this streamlines the workflow between the two solutions, reducing manual data entry and minimizing the risk of errors or overselling.

Accounting Applications

Another crucial IMS integration requirement relates to accounting applications. The goal here is to facilitate the seamless flow of financial data between the inventory management system and the accounting software. This is crucial to synchronizing sales, purchases, and inventory-related transactions while ensuring accurate and consistent financial records.

API Integrations

API (Application Programming Interface) integrations are ones that allow the inventory management system to communicate and exchange data with other software applications. There’s little value in having an IMS that can’t “talk to” shipping carriers, dropshipping platforms, point-of-sale (POS) systems, etc. APIs are what help facilitate microservices in supply chain software. As time goes on, such integration will only become more crucial to profitability.

Final Thoughts

At InventorSoft, we have our fingers on the pulse of the latest supply chain technology trends. Our team has more than a decade of experience working in the supply chain software development space and can help design an Inventory Management System that incorporates all the essential features outlined above.

Looking to implement a supply chain management system? Want to know more? InventorSoft can help.

Related articles

10 Top Outsourcing Pricing Models to Consider in 2024 - InventorSoft

Comparison of TOP 14 Node.js Frameworks (2023) - Inventorsoft

IT Budget Planning 2026: How Tech Leaders Can Win in an Uncertain Year

- What Is an Inventory Management System?

- Top Inventory Management System Features by Category

- Inventory Management Features to Consider

- Essential Requirements of an Inventory Management System

- Crucial Integration Requirements

- Final Thoughts