8 Crucial Supply Chain Management Software Requirements

The COVID-19 pandemic left the global supply chain in pretty poor shape. However, that hasn’t done anything to stem the tide of market demand for a wide variety of products. To make matters worse, analysts continue to warn of recessions on various scales, trade wars, and severe delays due to environmental changes around the world. These threats, coupled with truck driver shortages and other difficulties, have left many logistics business operations wondering, “What’s next?”

Fortunately, supply management software technology continues to improve at all levels. Not only do these new systems help reduce operational complexity, but they can also help increase efficiency and control costs at a time when either can be a major benefit. But how does one identify the right supply chain management system or systems for their business? Moreover, what are the most important supply chain management software requirements? If you’re seeking supply chain software development services, these eight features are essential.

Supply Chain Management software has numerous benefits. For instance, it allows companies to source raw materials more easily, better control product life cycles, and monitor various touch points while also centralizing data. Meanwhile, the right solution can provide managers with real-time updates on deliveries, allowing them to better plan for disruptions, maximize visibility, and increase accountability and efficiency.

But before simply choosing any SCM software solution, it’s crucial to determine which features your business needs for optimum supply chain execution. This checklist below covers the requirements that are often most critical to companies’ success.

Warehouse Management

A warehouse management system, also known as a WMS, can drastically improve a user’s control over the operations taking place at the physical warehouse. With this system, users can easily visualize and dictate everything from labor management and floor space to materials and operational protocols. Other key features include inbound processing, integrated labeling, storage optimization, KPI report management, and cross-deck planning.

Most WMS protocols come as part of a larger suite of solutions, but others can be implemented as stand-alone systems. That said, the latter choice can be problematic if, for any reason, the WMS will not properly integrate with other software. Selecting an entire suite can help avoid such problems, especially if that suite can be customized to your company’s unique needs and supply chain requirements.

Inventory Management

An inventory management system is one of the most basic and crucial features of any supply chain management software. Such solutions allow for real-time inventory level tracking, and automated reordering based on pre-set thresholds, and allow users to analyze inventory data to make informed decisions about purchasing and stocking.

In the context of supply chain management, inventory management software plays a critical role in ensuring that businesses have the right level of inventory on hand to meet customer demand while also minimizing inventory costs. By providing real-time visibility into inventory levels, inventory management software enables businesses to optimize their stocks, reduce stock-outs, and minimize excess while improving overall inventory control.

Transportation Management

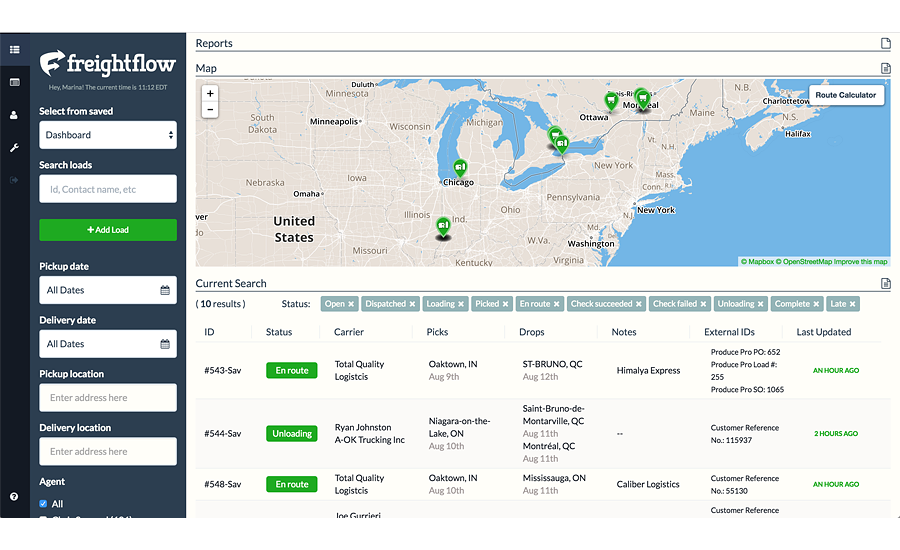

A transportation management tool or transportation management software (TMS) is essential for organizing and optimizing everything related to mobile operations. A TMS allows users to plan and execute shipments, track and monitor freight movements, and manage carrier relationships. When used properly, a TMS can also help businesses to reduce transportation costs, improve efficiency, and enhance the overall visibility of their supply chain.

Though each solution comes with its unique features, most will include a shipment planning and optimization function to help users find the best routes, modes of transportation, and carriers to meet their shipping requirements. They will also include a carrier management function to manage supplier relationships, track supplier performance, etc. Other important functions include freight tracking and visibility, as well as simplified freight payment and auditing.

Example of transportation supply chain system

Example of transportation supply chain systemMonitoring & Planning

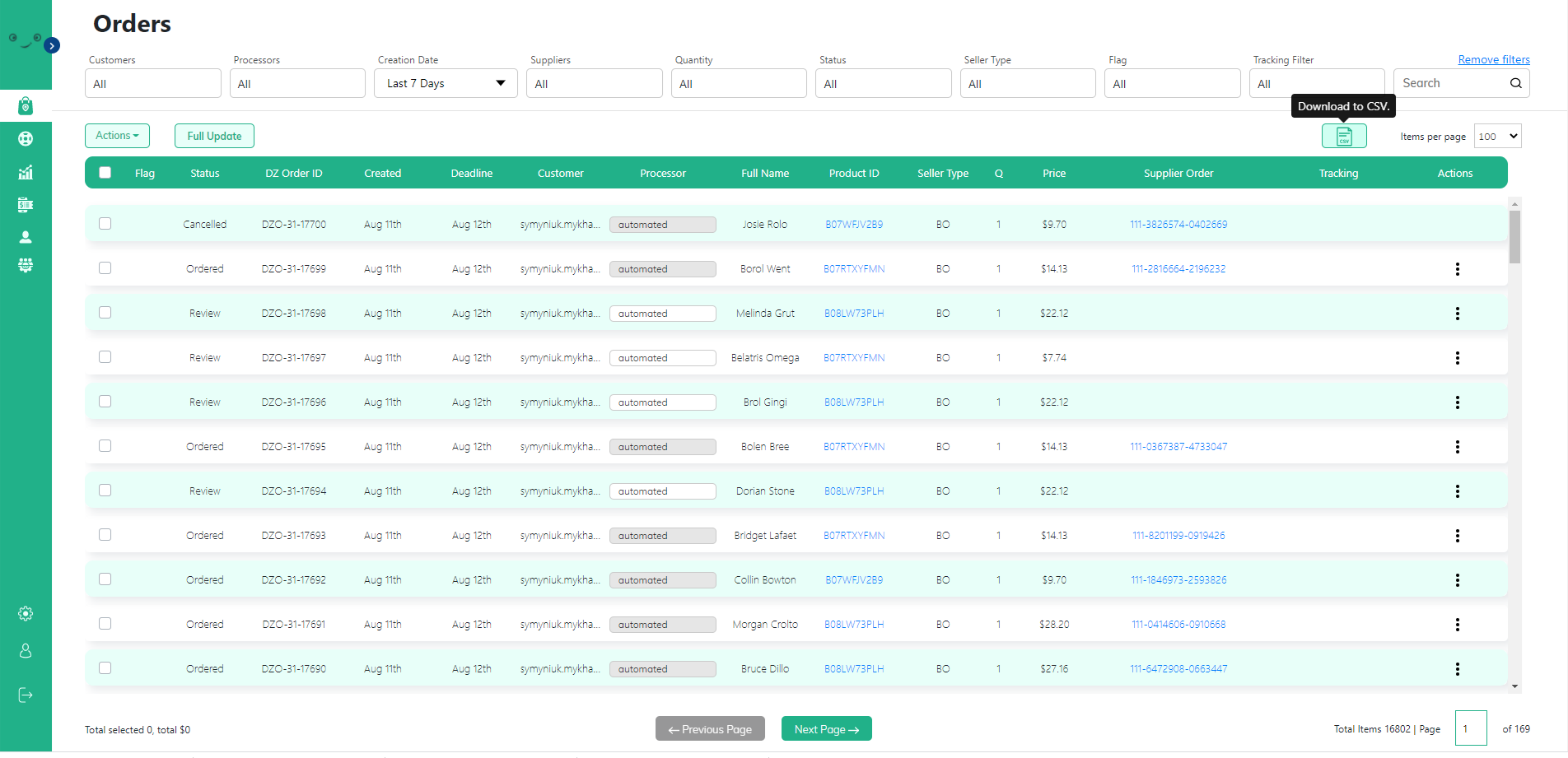

Proper monitoring and supply chain planning are essential to managing any supply chain, regardless of size or complexity. These types of tools provide valuable information on shipping dates, times, IDs, order numbers, and a wide range of freight data. With this information in hand, users can track key performance indicators to assist them in making better-informed decisions.

Most of these tools will be delivered in the form of a centralized dashboard from which users can see a wide range of manufacturing, procurement, and logistics data all at once. Common features include visual supply chain maps, in-transit status updates, demand planning, and demand forecasting, and even supply chain simulation. The resulting data can also be used to reduce costs and improve overall forecasting.

An example of a supply chain management solution from our side is Dropyzon. The portal enables drop-shipping clients to place orders on Amazon, with direct delivery to their customers, while also facilitating the discovery of products at the most competitive prices across the Amazon platform. Additionally, it generates a tracking number and dispatches the item directly to the drop shipper's customers. We helped our client to build this platform from scratch.

Example of order management system

Example of order management systemSupply Chain Analytics

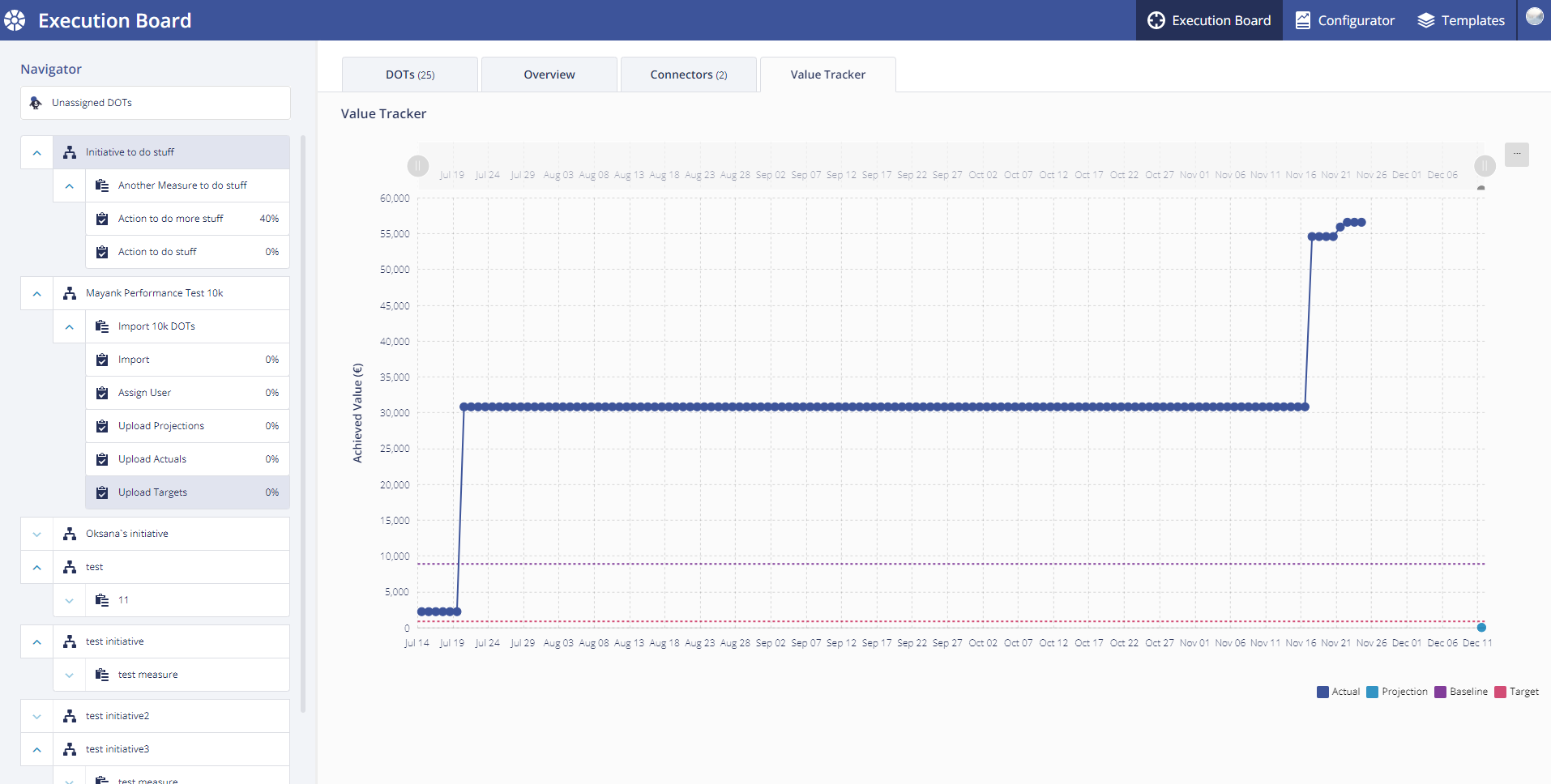

Now more than ever, supply chains need to evolve and improve to stay competitive. This has led more and more users to seek out software solutions that can not only support their supply chain but evaluate it as well. Such analytical software suites typically use business intelligence metrics to determine where supply chain issues stem from and how users can better manage risks. In many cases, they can even use predictive analysis to forecast potential problems. Among the many features of these systems are demand forecast accuracy analysis, KPI tracking, and integration with information management systems. If quality management and quality control are high priorities for your business, supply chain analytics can help.

As an example, we worked with AIO impact, the product created by Aioneers, which handles the analytics, decision support, and digital execution of supply chain management. Together with them, we developed a workflow process for this, utilizing a cloud-based infrastructure for both the backend and frontend. Our team helped to implement such features as an executive board, connectors, and digital object twins.

Example of supply chain analytics system

Example of supply chain analytics system Sourcing & Supply Management

Sourcing procurement and supplier management tools provide users with a unique approach to supply chain evaluation. For instance, many of these systems are programmed to look at costs, supplier quality, contract management, and other related issues. Used properly, they can aid in sourcing and procurement of supplies and raw materials, while also helping to technically assess the relationships between vendors and companies. Ultimately, this aids boost overall efficiency and reduces the occurrence of supply chain mix-ups in establishing key tracking methods.

Technical Features

Every software solution, including those for supply chain management, will come with its own suite of technical features. Though many are similar, others are different to the point that they can dramatically impact the final product's functions. Prospective customers should make sure to pay attention to security features like encryption standards and audit trails, but also cloud-based solution deployment, OS standards, fault tolerances, and more. Last but not least, companies need to assess how well their new system (or systems) can integrate with other tools and APIs.

Collaboration Features

Speaking of collaboration, such features are crucial to helping businesses expand their partnerships and increase the breadth and effectiveness of their supply chains. With a highly collaborative option, users can provide their partners with accessible shipment status data, transparent inventory models, and much more.

Also, the features embedded in these resources make it possible for multiple organizations to work on a single project, ensuring all stakeholders are always on the same page. This also eliminates the need for labor-intensive communication efforts while automating most aspects of the collaboration process. Ultimately, this allows users to expand their reach, scale their supply chain operations, and generally increase the sophistication of their business approach.

How Can Inventorsoft Help You?

Inventorsoft is a leading supply chain software development company with nearly a decade of experience developing supply chain management software. We recognize that effective supply chain management is essential to both the smooth operation of your day-to-day business and your prospective business growth. That’s why we help our clients find the necessary solutions for their supply chain needs, including all the necessary features and requirements listed above.

Among the many benefits of adopting SCM systems is that you get supply chain process optimization. This ensures you can upgrade and enhance your supply chain to maximize efficiency and productivity. We also help ensure you receive a regular supply of transaction data so you can deliver high-quality service to your clients. Of course, we help you find everything you need to monitor your resupply chains in real-time, capitalizing on opportunities and avoiding problems with enhanced nimbleness.

We help you find SCM solutions that embrace a whole new level of transparency, so you and your clients get a better understanding of your process and how it can be improved.

Final Words

Now, as you understand the essential characteristics of SCM software and how they affect supply chain processes better, it’s time to create your inventory of supply chain management software requirements. The best way to start is to look at your own business processes and attempt to identify what the perfect integrated system would look like for your company.

Depending on your business requirements, you may seek out a more robust procurement management system. You might desire to manage supply chains in ways that maximize customer satisfaction, and priorities in asset management, retail planning, or procurement processes.

While there are undoubtedly individual tools for customer relationship management, order management, and product lifecycle management, a fully integrated system could give you the competitive advantage you need to thrive in uncertain times.

At Inventorsoft, we’re confident we can help you find the solutions you need to meet your supply chain management goals.

Related articles

10 Top Outsourcing Pricing Models to Consider in 2024 - InventorSoft

Top 10 Essential Functional Requirements for Warehouse Management Systems

Dedicated Team Model - What It Is, Pros & Cons

- Warehouse Management

- Inventory Management

- Transportation Management

- Monitoring & Planning

- Supply Chain Analytics

- Sourcing & Supply Management

- Technical Features

- Collaboration Features

- How Can Inventorsoft Help You?

- Final Words